- 603, Luv Kush Tower

Exhibition Road Patna – 800 001, Bihar

- CIN

U27310BR1992PTC004871

Technologies

Coal Handling

BALAJEE HITEC performs complex design and engineering activities for conventional sequence of coal blend handling for carbonization: receipt, de-freezing, preliminary crushing, stocking, proportioning of coals, supply of coke oven and by product production wastes to coal blend, finishing grinding, mixing and transportation of coal blend to coal tower

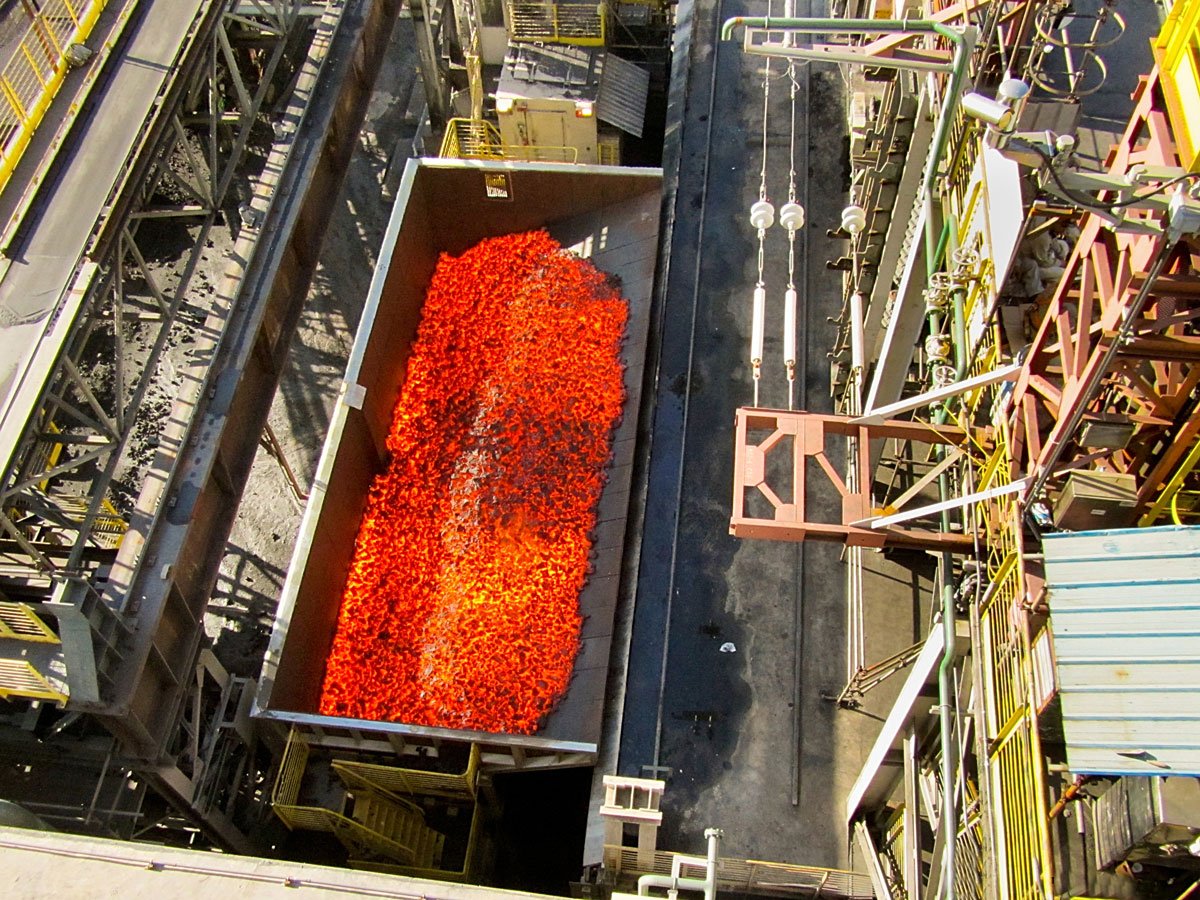

Coke Making

BALAJEE HITEC executes complex designing of coke oven plant facilities: coke oven batteries for production of blast furnace and foundry coke; ovens for production of special kinds of coke; pushing emission control systems; coke dry cooling plants; coke wet quenching complexes; coke transportation, handling, screening, uploading and storage facilities; coal towers; garages for repair of coke oven machines; hangars for erection of coke oven batteries brickwork; refractories, materials and equipment storage.

By-Product Recovery Plants

Main design facilities: By-product recovery plant. The plants of hydrogen sulphide recovery from coke oven gas to produce sulphuric acid or sulphur. Crude benzene processing plants. Tar processing plants. Various binders’ preparation units. Tank batteries for liquid products. Storages for bulk products storing, packaging and loading. Coke oven gas fine purification units for long-distance gas transportation. Central plant laboratories. Liquid waste products utilization unit. Systems of by-product plants' equipment sealing. Fuel production units, including motor fuel, from coal and other raw materials. Technical projects of individually manufactured equipment.

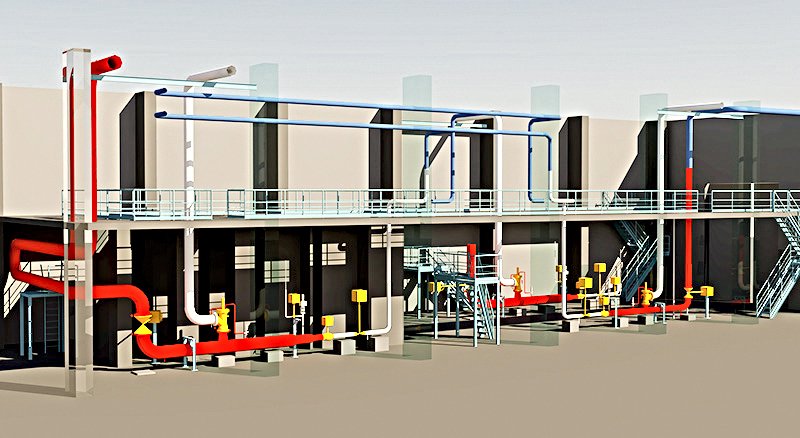

Heat-and-Power Engineering

Production of steam with various parameters and highly efficient generation of electric energy due to using secondary energy resources from iron & steel making plants, coke oven and by-product recovery plants as well as fossil fuels: Selection of optimal system for co-generation of steam and electric power on the basis of common heat and gas balance of production plant. Ensuring low prime cost of the generated steam and electric power due to using secondary energy resources. Using up-to-date equipment from the leading manufacturers (boilers and steam turbines of individual manufacture, gas turbines, gas reciprocating engines, etc.).